Some Styles of Run Resistant Hosiery are Available at the Shop Section!

This article is by T. Gallagher from USA, an industry expert and a person with great knowledge about different types of run resistant hosiery. We express such gratitude to him for taking the time to write for Fantasy Stockings blog and share his knowledge.

This is a package of Brooke’s run resistant pantyhose.

See if you can relate to this story. Its Monday morning, you hit the snooze on your alarm clock one too many times, and now you are running late for work. You are in a full blown frenzy desperately trying to get out the door. You rush to brush your teeth, shower, get dressed, do your hair, and get your makeup just right. You open a new package of your favorite pantyhose. You slip your feet in, gently slide the hose up your legs, tuck yourself in, only to realize that you have a huge run up the back of your leg.

Seriously, what business professional wants to be in the middle of a presentation and realize she has a glaring unsightly run up the side of her leg for all to see? For that matter, who wants to be at an elegant dinner party or wedding and discover a snag has opened up into an unsightly hole or ladder? Ladders, rips, runs, and snags are often cited by women as the main reason they don’t wear or stopped wearing hosiery including pantyhose stockings and tights.

There is a solution: Run resistant hosiery technology. Run resistant hosiery technology does exist and has been around for decades. When manufactured correctly, hosiery that utilizes run-resistant technology is not only more durable it actually increases the appeal and experience of wearing hosiery. Run-resistant hosiery technology is relatively inexpensive to incorporate in the manufacturing process.

For years, the hosiery industry chose to shelve run-resistant technology. Hosiery manufacturers were slow to embrace and invest in new advances in sewing and textile equipment and processes.

They were content with the status quo and followed the short sighted logic that they would lose business and profit if they made hosiery that was durable. "Sell more to make more profit" was the prevailing thought process of most hosiery manufacturers. Instead of making a product that would last, they chose to make a product that was prone to fail. Had the manufacturers incorporated run resistant technology when it first became available, one could argue more women would still be wearing hosiery today.

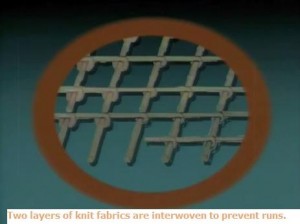

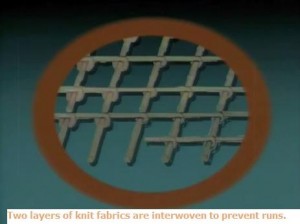

Run resistant technology for hosiery involves a two-step process.

The first step in producing run resistant hosiery involves changing how the fibers and threads forming the hosiery are stitched, machined, or woven together. In regular hosiery (prone to ladders, runs, rips, and snags) the fibers and threads are plain stitched together which is a looser weave or stitch process. In run-resistant hosiery, the weave or stitch is tightened up. Tightening the weave is referred to as the knotting process or lock stitching. In some hosiery, the knotting process or lock stitching is focused on key areas prone to runs including the waistband, panty, crotch, gusset, heel, toes, and the transition point between the panty and leg. In true run resistant hosiery, the knotting process or lock stitching is incorporated throughout the entire product from waistband to toe.

The second step in run-resistant hosiery involves blending the original nylon fiber with another synthetic or natural fiber. Some examples include acrylic, acetates, cotton, lycra/spandex, polyesters, polyethylene, polyurethane, and polyvinyl, rayon, silk, and wool fibers. The most common blend in hosiery is to combine nylon with lycra/spandex. By increasing the amount of lycra/spandex content, the more run-resistant the hosiery becomes. For example, a pair of pantyhose with a 80% nylon and 20% lycra/spandex blend is going to be more run resistant or more durable than a pair with a 90% nylon and 10% lycra/spandex blend. One drawback to incorporating more Lycra/Spandex into the blend is the denier or thickness of the hosiery increases. A true sheer pantyhose blend would have a 86% Nylon and 14% Lycra/Spandex content. Anything more would result in a heavier denier or thicker ‘tights like’ hosiery product.

run resistant hosiery won’t snag easily

A shortcut would be to stop at the stitching process. However, the finished product would be rougher and uncomfortable to wear. Likewise, blending nylon with lycra/spandex fibers alone would still lead to ladders, rips, runs, and snags. To achieve wearable run-resistant hosiery both steps must be utilized.

An early example of a run resistant hosiery brand that I remember was the Brooke Shields Forever Sheer Non-Run Pantyhose. Brooke would sell her brand of hosiery on infomercials only. During her half hour commercial she would take knives, forks, staples, scissors, and other sharp objects to her hose and show they would not snag or run. The visual demonstrations were quite effective and consumer response was strong.

More recently, Microfiber technology has been incorporated in the manufacturing of hosiery as a way to increase run resistance. Microfiber technology is also a process of blending fibers. Microfibers are more commonly synthetic fibers although some natural fibers have been incorporated in the process. The shape, size and combinations of synthetic fibers are selected for specific characteristics, including: softness, durability, breathability, thermal regulating, and wicking properties. Microfiber is also very elastic, making it ideal for hosiery. Microfibers allow for stronger more durable hosiery at lower denier or thickness. Not only does microfiber technology enhance run-resistance… Microfiber technology increases overall comfort, durability, fit, and feel of hosiery. Have you ever felt hot or tend to perspire wearing hosiery? How about a binding sensation or itchy feeling from a pair of pantyhose? Ever have a pair of pantyhose or tights lose their shape, sag, or bunch up/wrinkle at the ankle? Thanks to the incorporation of microfibers into hosiery those problems can also be a thing of the past.

High end manufacturers of hosiery in Europe were the first to incorporate run-resistant technology including the use of microfibers in their hosiery products. Brands like Wolford, Falke, Kunert, Gypsy, Gerbe, Filodoro, Elbeo, Cette, Pretty Polly, and Transparenze all have incorporated run resistant technology and the use of microfibers into their product lines. United States brands like Hanes, Berkshire, Just My Size, Leggs, No-Nonsense and Silkies were soon to follow. They all have released run-resistant hosiery in their product lines. Asian manufacturers have also started producing lines of run resistant hosiery.

One can only hope that hosiery manufacturers have learned from their mistakes of the past… opting for the wise choice to embrace improved processes and technology that lead to better products for their customers.

Have you tried or do you have a favorite brand of run resistant hosiery? Tell us about it and share your story below.

Vintage Youtube videos for Other Run Resistant Pantyhose

1990 Run Free Pantyhose commercial

K-tel “Perfect Pantyhose” commercial

*Friends, please check out the shop section, this is what funds this blog. At the moment Gatta and Fiore run resistant hosiery is available to buy.*

Both Gatta and Fiore brands are from Poland, with factories just a short train ride apart. They keep an eye on each other, copy each other, and so on, just like any good competitors. In general Gatta is more popular and has a wider selection. The price is quite similar.

Both Gatta and Fiore brands are from Poland, with factories just a short train ride apart. They keep an eye on each other, copy each other, and so on, just like any good competitors. In general Gatta is more popular and has a wider selection. The price is quite similar. Here are my comments so far:

Here are my comments so far: Toe reinforcement: Gatta has sheer toe, Fiore has invisibly reinforced toe. I rarely get runs, but I hear from other people that any kind of reinforcement helps with durability.

Toe reinforcement: Gatta has sheer toe, Fiore has invisibly reinforced toe. I rarely get runs, but I hear from other people that any kind of reinforcement helps with durability.